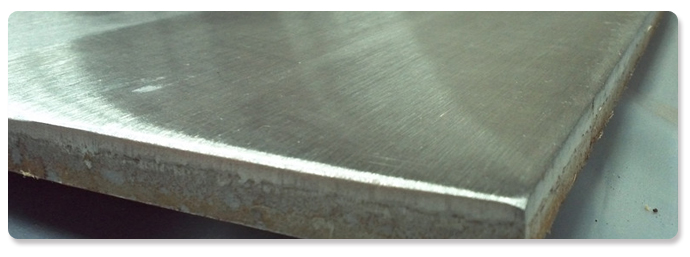

Clad Steel

You Are Here -> Home ->clad steel

clad steel plate Suppliers

clad steel plate Stockists

Cladding is the bonding together of dissimilar metals. It is different from fusion welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling sheets together under high pressure. CRA clad and lined steel has been available in various forms and it s widely used in the oil and gas industries. The specific requirements of this industrial sector, methods of manufacturing clad plate, pipe and fittings are given along with welding details and information on some field applications of clad and lined products.

MD Exports LLP inc is largest suppliers of clad steel plate. we are supplying clad steel platein Saudi arabia, Kuwait, Qatar, Oman, Yemen, UAE, Iran, Turkey, Kazakhstan, Greece, Singapore, Thailand, Indonesia, Vietnam, South Africa,South America,Brazil, India, Australia, Egypt.we assured our client that we are standing behind our product which we have supplied as well as we issued a quality certificate along with our product which we manufacture supplies and exports

we are also manufacturers, suppliers, exporters and stockists of Stainless Steel plate, Quenched & Tempered Steel plate , Pressure Vessel Steel plate, High Strength Steel plate, High Nickel Alloy plate, HIC plate, Corten Steel, Clad plate, Alloy Steel plate

The selection of clad steel requires decisions to be made regarding:

- the optimum choice of CRA/backing steel combination

- the selection of manufacturing method appropriate to the part which is clad

- the approach to the fabrication.

Cladding Process as below:

Roll Welding

In roll welding, two or more layers of different metals are thoroughly cleaned and passed through a pair of rollers under sufficient pressure to bond the layers. The pressure is high enough to deform the metals and reduce the combined thickness of the clad material. Heat may be applied, but is not necessary if one of the metals is ductile. Bonding of the sheets can be controlled by painting a pattern on one sheet; only the bare metal surfaces bond, and the un-bonded portion can be inflated if the sheet is heated and the coating vaporizes. This is used to make heat exchangers for refrigeration equipment.

Explosive Welding

The most common explosive metalworking technique is explosive welding, also known as Explosive bonding or explosive cladding.It is the bonding of two or more dissimilar metals with the aid of explosives. In explosive welding, the pressure to bond the two layers is provided by detonation of a sheet of chemical explosive.

No heat-affected zone is produced in the bond between metals. The explosion propagates across the sheet, which tends to expel impurities and oxides from between the sheets. Pieces up to 2 x 6 metres can be manufactured. The process is useful for cladding metal sheets with a corrosion-resistant layer

Laser Cladding

Laser cladding is a method of depositing material by which a powdered or wire feedstock material is melted and consolidated by use of a laser in order to coat part of a substrate or fabricate a near-net shape part (additive manufacturing technology) .It is often used to improve mechanical properties or increase corrosion resistance, repair worn out parts,and fabricate metal matrix composites.

Available Grade

- ASTM A263( Standard Specification for Stainless Chromium Steel-Clad Plate)

- ASTM A264(Specification for Stainless Chromium-Nickel Steel-Clad Plate)

- ASTM A265(Standard Specification for Nickel Base Alloy – Clad Plates)

- ASME SA-263(Specification for Stainless Chromium Steel-Clad Plate)

- ASME SA-264(Specification for Stainless Chromium-Nickel Steel-Clad Plate)

- ASME SA-265(Standard Specification for Nickel Base Alloy – Clad Plates)